A Peel-Off Graphene Sheet Fabricated from Camphor

- News

- 2.6K

Graphene, a recently discovered wonder material, is increasingly sought after for its superior electrical, thermal, optical and mechanical properties. It finds use in the manufacture of optoelectronic devices such as detectors, sensors, and solar cells.

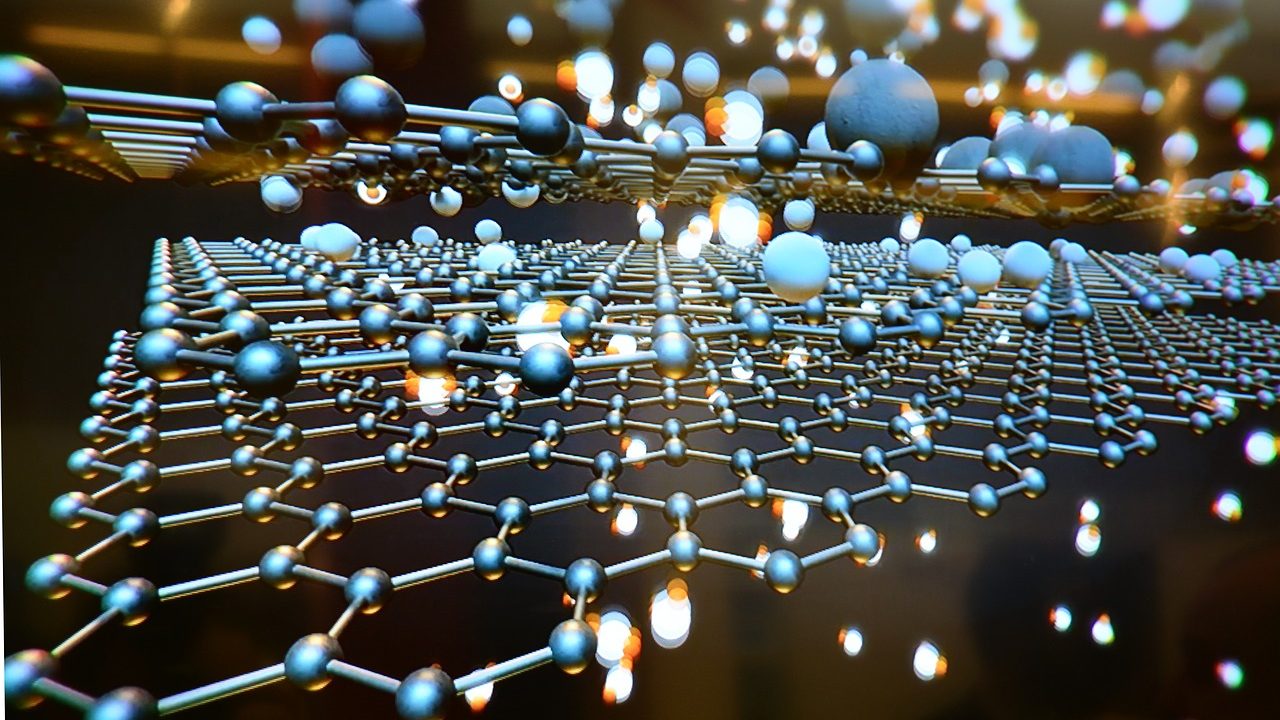

Graphene is made up of a one-atom-thick, honeycomb-like structure of carbon atoms. A significant challenge faced by scientists is the fabrication of large-area graphene sheets for devices. Finding a ‘green’ source for the carbon atoms is another hurdle.

Indian researchers have now developed a new method to fabricate graphene sheets from camphor — a readily available ingredient often used in religious rituals.

“Camphor is a plant product with abundant carbon elements required to derive graphene. All it needs is restructuring — breaking and making of chemical bonds— of the carbon atoms. So we explored the possibility and achieved this rearranging of elements of camphor to get graphene mono-layers,” said Dr. Indrajit Mukhopadhyay, lead researcher of the study at the Pandit Deendayal Petroleum University, while speaking to India Science Wire.

Camphor was subjected to a thermo-chemical process called pyrolysis and then deposited by chemical vapor deposition technique on a commercially available 25-micron thick copper foil. Camphor was heated and its vapors were sent into a tubular furnace and heated further to 1020 degree Celsius. The vapor was then treated with nitrogen and hydrogen gases to eliminate unwanted components of camphor.

Copper was used as a substrate since carbon has negligible reactivity to it. Moreover, copper itself acts as a catalyst for the restructuring of carbon atoms, which were deposited in a monolayer over 1inch x 1inch foil. The novelty of the method lay in the recoverability of the graphene sheet. “With our technology, the fabricated graphene layer can be extracted and transferred to other substrates depending on the application,” added Dr. Mukhopadhyay.

Once the graphene layer is developed on the foil, copper can be removed by chemical methods, leaving behind a pure monolayer of graphene. This layer can be suspended in a solvent and transferred to other substrates like aluminum, silica or a polymer, as per the device requirements, he explained.

The graphene sheets were subjected to rigorous laboratory tests to evaluate the structural and morphological parameters. The results established its uniformity and robustness. “We have further demonstrated its use by utilizing it in a highly sensitive infrared detector”, he said.

Besides Indrajit Mukhopadhyay, the research team included Harsh A Chaliyawala, Roma Patel and Abhijit Ray from Pandit Deendayal Petroleum University, Gujarat; and Narasimman Rajaram from CSIR-National Institute for Interdisciplinary Science and Technology, Thiruvananthapuram. The study results have been published in the journal ACS Omega. (ISW)

Susheela Srinivas

If you liked this article, then please subscribe to our YouTube Channel for the latest Science & Tech news. You can also find us on Twitter & Facebook.